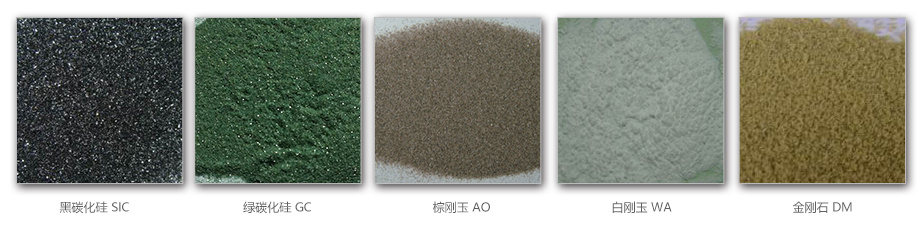

Grinding sand review

Performance Comparison

SIC silicon carbide is the top selection and featured by sharp and wearable characteristics, high cost performance and wide applicability;

AO aluminum oxide is commonly used in processing soft materials such as copper, aluminum and wood;

WA ceramic corundum is featured by strong cutting force and good self-sharpening and can be used for textile griting and accurate grinding etc.

Vickers hardness: DM > GC > SIC > WA > AO

Cutting force: DM > GC > SIC > WA > AO

The SIC abrasive filaments are the most widely applied and the AO abrasive filaments are suitable for precision polishing and low-hardness material grinding.

I. Black Silicon Carbide (SIC)

Silicon carbide usually refers to the abrasive material of black silicon carbide and black silicon is the shortened form.

The black silicon carbide is made of quartz grit with petroleum coke as the main raw material, and it is smelted through high temperature in electric resistance furnace. It is black crystal with micro-hardness of HV3100-3280, is brittle and sharp, has certain electrical conductivity and thermal conductivity, and its hardness and mechanical strength are higher than those of corundum.

The SIC abrasive filaments are widely applied in steel, textiles, PCB needle brushes, stone archaizing brushes, and various abrasive tool brushes etc.

II. Green Silicon Carbide (GC)

Green silicon carbide and black silicon carbide share basically the same performance but they are different in raw materials and manufacturing processes; the green silicon carbide is green translucent crystallization and has microhardness of HV3280-3400 slightly higher than that of black silicon carbide.

The GC abrasive filaments are usually applied in abrasive tool brushes for gemstones, optical glass, and ceramics.

III. Brown Aluminum Oxide (AO)

Aluminum oxide refers to the abrasive material of brown aluminum oxide.

The brown aluminum oxide is smelted by bauxite in electric-arc furnace. It is brown and its main chemical component is Al2O3. Its micro-hardness is HV1800-2200 smaller than silicon carbide but has tenacity higher than that of silicon carbide.

The AO abrasive filaments are applied in occasions of small grinding surface hardness and finish machining such as copper materials, aluminum materials, furniture, and precision parts etc.

IV. White Aluminum (WA)

Ceramic corundum usually refers to the abrasive material of white Aluminum (WA).

The white Aluminum takes Aluminum as the raw material and is smelted through high temperature in electric-arc furnace. It has white color and its main chemical component is Al2O3; its micro-hardness is HV2200-2300 slightly higher than that of brown aluminum oxide; it has slightly lower tenacity and better cutting characteristic.

The WA abrasive filaments are mainly applied in textile brush rolls and brush tools and can be processed into various beautiful colors.

V. Diamond (DM)

Diamond is a super hard material with sharp cutting edges and corner angles, good self-sharpening and high tenacity. Its grinding removal ability and efficiency are higher than those of other brands.

The diamond abrasive filaments have good grinding effects and high machining efficiency. They are expensive but still growing rapidly, and are mainly applied in super hard materials, hard grinding materials, and high value added industries such as machining tungsten steel, silicon plates, and precious gemstones etc.