"SCF” Super Cleaning Filaments

WOLF. SCF (super cleaning filaments) are also called all-cleaning filaments or abrasive filaments which are directionally developed based on brush usage characteristics, mixed with proper/appropriate/environment-friendly abrasive grit into nylon and made through spinning process, and are capable of polishing and decontamination. WOLF. SCF comply with hygiene and food safety regulations specified by FDA in the U.S.

WOLF has changed applicability of industrial abrasive filaments into SCF and expanded to civil use. The fully-DIY filaments aim to solve the problems in ordinary cleaning brushes such as cleaning dead angles in uneven surface and narrow space, poor cleaning performance, poor fouling removal, and low cleaning efficiency etc.

Performance advantages include referenced experiences such as scouring pad, sponge abrasive cloth, and abrasive paste, which belong to flexible polishing and decontamination materials.

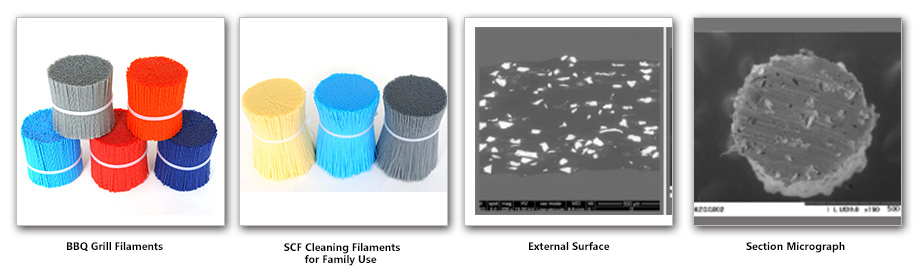

WOLF. SCF have rough/hard/small edges in the cross section and peripheral surface. Their friction is increased by point array contact and scraping friction and they can go deep into embossed patterns and small areas, clean and remove fouling in 360° degrees, and enhance cleaning efficiency and effects. In addition, they can save time and efforts to radically polish and remove heavy fouling such as the absorbed and deposited fouling matched with detergent so as to become fresh, bright and beautiful through one cleaning.

Operation modes of ordinary cleaning brushes: They use filament tips to contact/rub/scrape for de-fouling, usually adopt finer/harder filaments or are trimmed into suitable shapes to enable the filament tips to contact corners, but the effects are not good. This is because the pure nylon filaments have smooth side and rough section, and cause low cleaning efficiency, poor effects, and dead angles in cleaning especially for heavy fouling, narrow position, and uneven shapes.

Contrastively, WOLF. SCF have complete rough structure, increased friction force, and polishing and decontamination in 360° degrees, and can burnish and remove fouling in all angles once touch even the tiny area and irregular surface such as holes, grooves, and embossed patterns etc.

In general, when utensils are made, they need abrading to achieve the smooth outer surface. Therefore, the suitable WOLF.SCF can flexibly polish and de-fouling, effectively remove the surface dirt and attachments, and make the objects more polished without damage.

The usage characteristics should be considered for some softer materials, for example, for cleaning wooden cutting board, WOLF. SCF can quickly remove the residual tips or humic fouling from the surface, which is suitable for SCF usage characteristics.

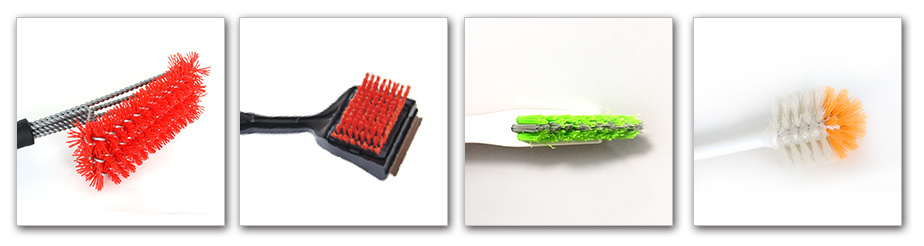

To sum up, to develop the super cleaning brush, WOLF suggests: Select the brush which can exert the SCF characteristics, use the filaments wholly or locally; firstly test the advancement of the application, and then design the novel brush style, and finally make a user-friendly super cleaning brush.

The all-cleaning brush has room for innovation and imagination and may become a new brush legend through designing, experience and marketing.

Success Case

Char-broil (http: www.charbroil.com) selling grills and cleaning tools has lead to apply WOLF. SCF into grill rack brushes since 2013; that is to say, under the cooling condition, the abrasive filaments can scrape and remove the attached dirt from grill rack grates or mesh surface in all angles with excellent performance, which have had good sales in the U.S. and European markets and achieved great success, and other brands have been racing to follow.

In 2017, a Japanese company adopts WOLF. SCF to be locally put into floor groove cleaning brushes with excellent performance.

Applicable materials: Ceramics, stone, steel, aluminum, and glass etc. and used for uneven shape or groove cleaning; usage reference:

•Kitchen polishing and de-fouling: Cooled grills, sinks, cutting boards, pots, food steamers, kitchen tables, sieves, and teapots etc.;

•Bathroom polishing and de-fouling: Close stools, bathtubs, glass, drainage exits, and shower rooms etc.;

•House polishing and de-fouling: Courtyard, swimming pools, ground and wall bricks, fish tanks, flower discs, and shoe soles etc.;

•Polishing, de-fouling and refurbishment: Ground surface in squares, factories and courtyard, swimming pools, outer wall, haulage motors, and protective guards etc.

SCF are advanced in overcoming problems in ordinary brushes such as uneven surface or narrow position, dead angles in cleaning, and poor de-fouling. Therefore, usage simulation tests should always be adopted to determine applicability and advancement so as to seek to exert the application of brushes with abrasive filaments, solve insufficiencies in current ordinary brushes, and wholly or locally adopt the abrasive filaments.

WOLF. SCF should be directionally developed based on brush usage characteristics so as to advance the brush performance such as time-saving, effort-saving, and good cleaning effects etc.

Time efficiency: The highly frequently-used brushes such as grill brushes are significant in quick and radical cleaning;

Cleaning effects: The unique cleaning and de-fouling ability is suitable for difficult cleaning places such as close stools and sink grooves;

Cleaning efficiency: Shorten cleaning hours for high cleaning workload such as uneven surface or fouling ground;

Comprehensive costs: Comprehensively consider labor, cleaning difficulty and cleaning time to discover application value.

The above product description is a reference for selection and application. Specific application tests should always be adopted for application or not.

The company claims not to guarantee the product applicability. The quality guarantee is only limited to ensuring that the supplied product quality is similar to the tried sample quality. No SCF replacement is provided.